TPS Quality Assurance Program

TPS continually strives to improve its Quality Assurance Program. Our well-defined and controlled processes of quoting, contract review, purchasing, receiving, inspection, processing, packaging, shipping, and inventory control combined with qualified and experienced personnel make it possible to meet or exceed customer requirements.

In addition, TPS performs designated source inspections for Boeing Mesa, Bombardier, Mitsubishi Heavy Industries, Nabtesco, and Sikorsky to ensure customer needs.

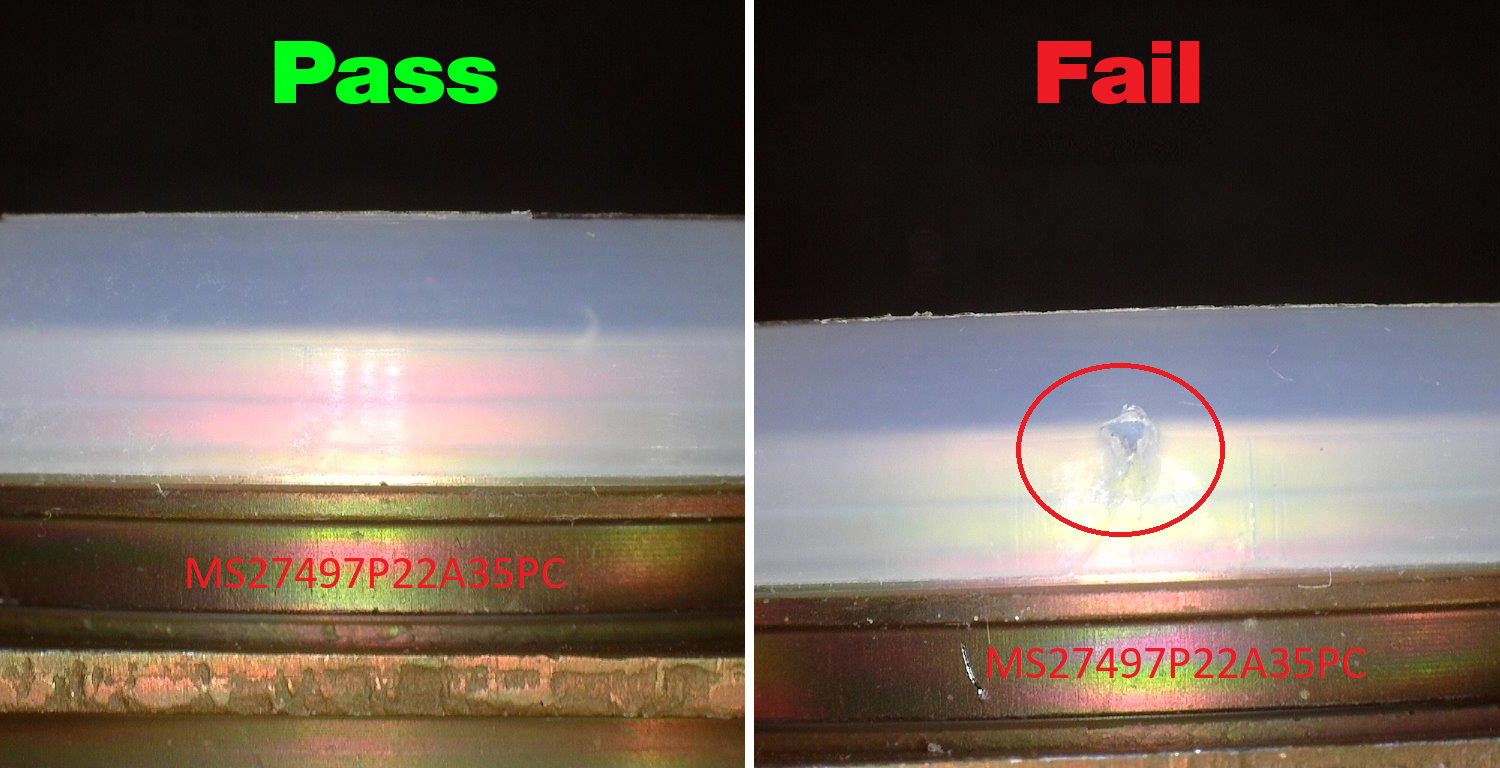

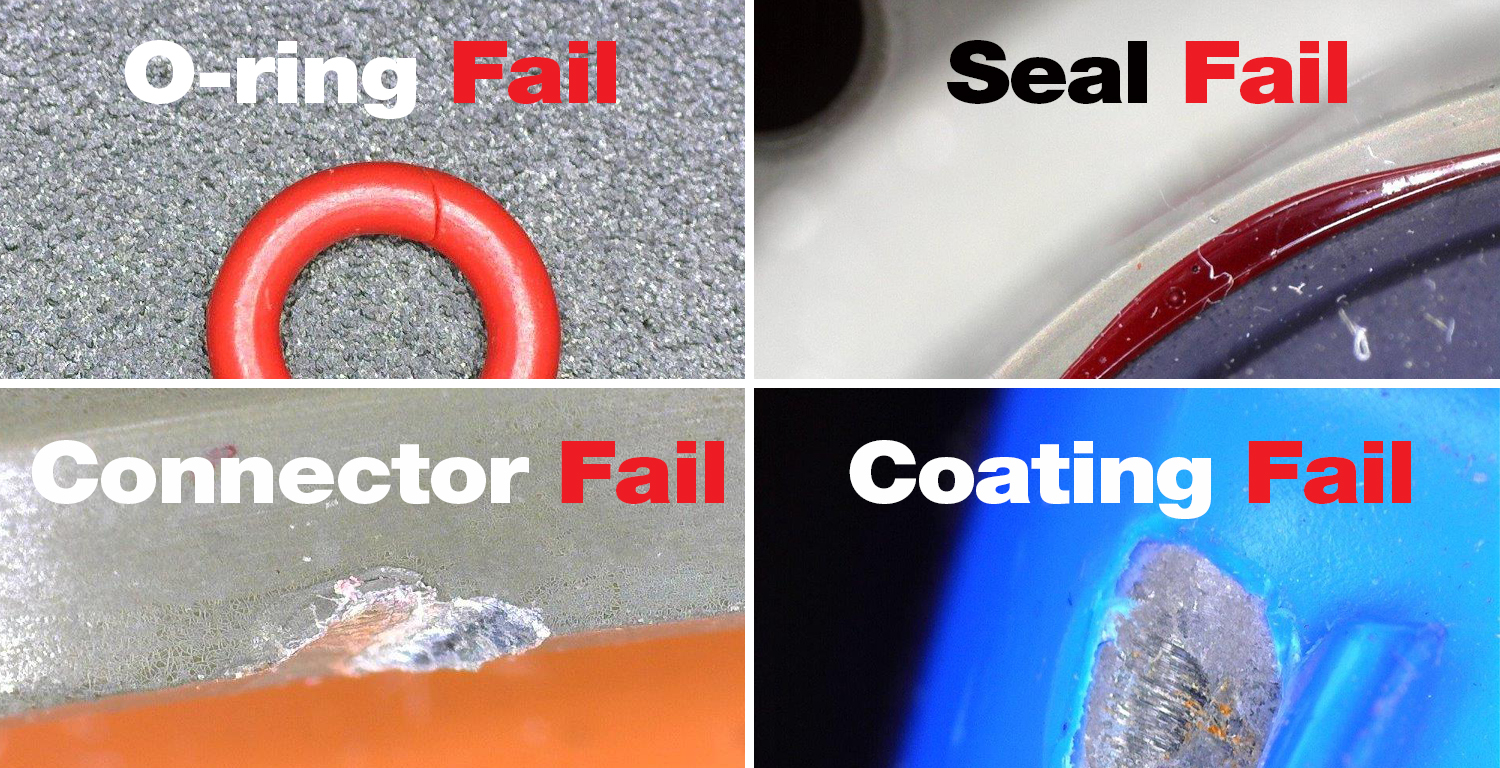

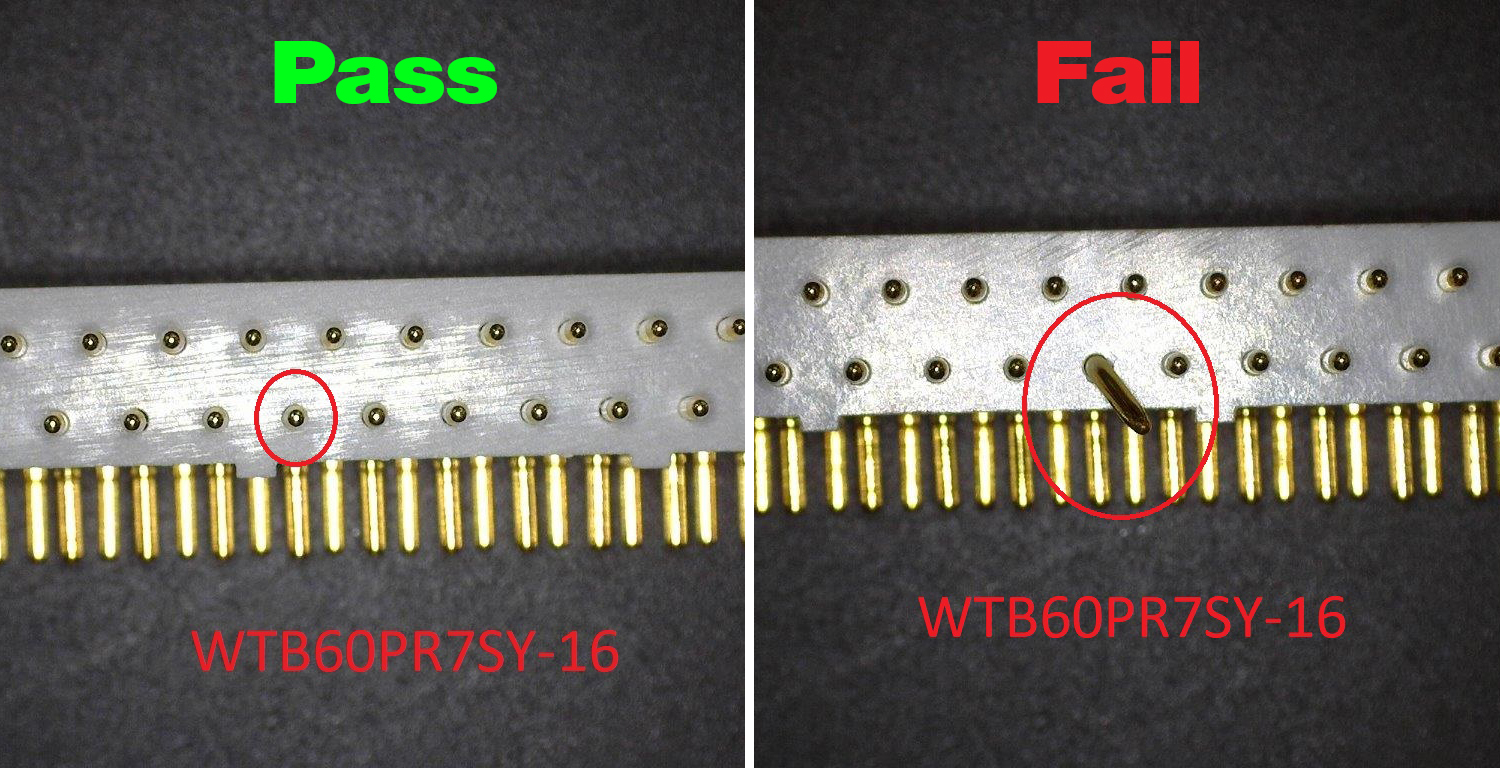

TPS Aviation utilizes inspection equipment such as Keyence, optical comparator, RW Hardness, Dino Cam, System 23, ESD workstations, and anti-static work stations for its inspection activities.

Certifications and Technical Assistance

TPS is committed to providing excellent customer service and quality products to the utmost satisfaction of its worldwide customer base of both commercial and military sectors. TPS is certified to ISO9001, AS9100 and various customer quality standards and requirements.

All aviation parts and components (with accompanying documents) are inspected to ensure they meet all specified requirements. Product quality and traceability is maintained through the inspection and stocking processes while rejected parts are segregated and disposed of according to standard industry guidelines.

Certificates

- Boeing D6-82479 APPENDIX ‘A’

- ISO 9001:2015 + AS9100D — Download Certificate PDF

- Approved supplier to Mitsubishi Heavy Industries, Ltd. — Download Certificate PDF

- Approved supplier for BAE Systems Regional Aircraft — Download Certificate PDF

- Approved supplier for the DLA — Download Certificate PDF

Government Department and Agency Licenses

- United States Department of State

- United States Department of Commerce

- Ministry of Defense, Japan

- TPS meets all regulatory requirements including DFAR, Counterfeit prevention, Conflict minerals, and REACH.

Supplier Quality Requirements

- TPS standards and requirements — TPS Quality Requirements PDF

TPS Worldwide Markets

Industry Service Recognitions and Awards

ALLFAST Fastening Systems1998

ALLFAST Fastening Systems1998

The Boeing Company2011

The Boeing Company2011

Bombardier Aerospace

Bombardier Aerospace

Defense Supply Center — Columbus2004, 2005, 2006

Defense Supply Center — Columbus2004, 2005, 2006

Defense Supply Center — Richmond2002, 2004

Defense Supply Center — Richmond2002, 2004

Vice Admiral Yoshinori Kawano, Commander Maritime Material Command2007

Vice Admiral Yoshinori Kawano, Commander Maritime Material Command2007

Lockheed Martin Aeronautics Company2010

Lockheed Martin Aeronautics Company2010

Communication Equipment Works, Kenzo Tsukada, General Manager1993

Communication Equipment Works, Kenzo Tsukada, General Manager1993

Mitsubishi Heavy Industries Ltd.2007

Mitsubishi Heavy Industries Ltd.2007

Northrop Grumman1998

Northrop Grumman1998

Shur-Lok1996, 1997, 1998

Shur-Lok1996, 1997, 1998

Teledyne Ryan Aeronautical

Teledyne Ryan Aeronautical

B&B Specialties, Inc.2010, 2011, 2012, 2021

B&B Specialties, Inc.2010, 2011, 2012, 2021

The Boeing Company2008, 2010, 2011, 2012, 2014

The Boeing Company2008, 2010, 2011, 2012, 2014

Defense Logistics Agency — Land and Maritime2010, 2012

Defense Logistics Agency — Land and Maritime2010, 2012

Defense Supply Center — Columbus2007

Defense Supply Center — Columbus2007

Vice Admiral Hitashi Murakami, Commander Maritime Material Command2005

Vice Admiral Hitashi Murakami, Commander Maritime Material Command2005

Vice Admiral K. Izumo, JMSDF Commander Supply Control Command2019

Vice Admiral K. Izumo, JMSDF Commander Supply Control Command2019

Lockheed Martin Aeronautics Company1998

Lockheed Martin Aeronautics Company1998

Nakamura Works, Naoki Hashimoto, General Manager1991, 1992

Nakamura Works, Naoki Hashimoto, General Manager1991, 1992

MS Aerospace2006

MS Aerospace2006

Raytheon Missile Systems2011, 2012

Raytheon Missile Systems2011, 2012

Shur-Lok

Shur-Lok

Boeing Defense & Space GroupFebruary 2011

Boeing Defense & Space GroupFebruary 2011

The Boeing Company2011

The Boeing Company2011

Defense Logistics Agency — Land and Maritime2011

Defense Logistics Agency — Land and Maritime2011

Defense Supply Center — Columbus2003

Defense Supply Center — Columbus2003

Vice Admiral Morifumi Takeda, Commander Maritime Material Command2000

Vice Admiral Morifumi Takeda, Commander Maritime Material Command2000

Gifu Aircraft Division, Hiroshi Tojyo1998

Gifu Aircraft Division, Hiroshi Tojyo1998

Mitsubishi Electric2008, 2009, 2010, 2011, 2015

Mitsubishi Electric2008, 2009, 2010, 2011, 2015

Mitsubishi Electric2003

Mitsubishi Electric2003

NASA/The Boeing Company

NASA/The Boeing Company

U.S. Small Business Administration1998

U.S. Small Business Administration1998

Sikorsky2018

Sikorsky2018